Rheology is a broad category of physics involving various types of instruments to help describe the flow behavior of just about any type of matter. Most rheologists are concerned with

- viscosity: a material’s resistance to flow,

- viscoelasticity: the tendency of a substance to flow under some conditions and snap back to its original position under others, and

- Newtonian behavior: how the viscosity changes as the substance is agitated.

They do so using rheometry, the use of a machine to determine the rheological properties (such as listed above) of a material. There are several configurations of machinery that are commonly used in rheometry, each of which can offer slightly different information about the fluid being measured. Each industry has their own preferred method of gathering rheological data, and the MCL’s TA Instruments DHR20 rheometer has a modular format and customizable test methods for this purpose. The DHR20 has more configurations and options than those listed here, reach out to the MCL for inquiries about its capabilities.

Rheology terminology

| Symbol | Term | Definition |

|---|---|---|

| M | Torque | Force required to rotate the top fixture |

| ɷ | Angular Velocity | How fast the top fixture rotates |

| θ° | Cone Angle | Angle of the tip of a cone geometry measured from the horizontal |

| Shear Rate | The rate at which the fluid is deformed (in a rotational viscometer, this is virtually the same as angular velocity) | |

| σ | Shear Stress | The shear stress experienced by the fluid. This can be visualized as the fluid being broken up into a stack of disks with the shear stress as the friction between the disks. |

| η | Viscosity | How much a fluid resists flow |

| R | Cone/Plate Radius | Radius of the upper geometry measured from the central axis of rotation |

Cone-and-plate vs Parallel plate geometries

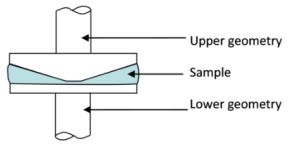

Cone-and-Plate geometry

For most applications, the cone-and-plate setup is not significantly different from the parallel plate setup. It is meant to provide a constant shear rate to the sample, no matter its distance from the center of the plate. The tip of the cone traditionally rests on or near the lower plate, so the gap, or the distance between the plates is not adjustable. While this does not create a problem for liquids, slurries or suspensions with measurable particle sizes should not be used in the cone-and-plate geometry, as their particles could get trapped beneath the center of the cone.

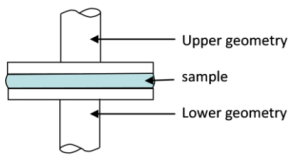

Parallel Plates geometry

With a parallel plate viscometer, the shear rate increases as you move radially outward from the center of the plates. This variation in shear rate can sometimes cause measurements to be inaccurate if the material being measured behaves drastically different under small shear rate changes. Parallel plates’ main advantage comes with a highly-adjustable gap. For slurries and suspensions with measurable particle sizes, it is recommended that the gap be at least 10x the maximum particle’s size. If possible, the gap should be raised to 100x the max particle size.

Oscillation vs Continuous Flow

Most rotational rheometers have the capability to oscillate back and forth or to spin continuously, called flow mode.

Oscillation Mode

Oscillation mode is typically used to measure viscoelastic properties, or the tendency of a substance to have elastic behavior when deformed quickly, but viscous or flow behavior when deformed slowly. Typically, this involves observing a sample’s relaxation time: the time for the internal stresses of the fluid to equilibrate after deformation.

Flow Mode

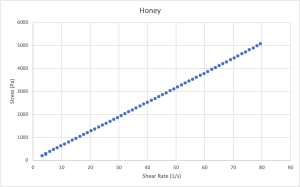

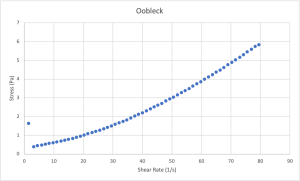

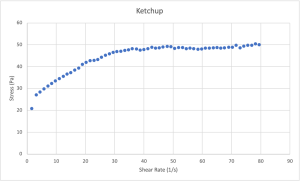

Flow mode is useful for measuring viscosity. In flow mode, the top fixture, whether cone, plate, or other, spins while the machine measures the resistance to this spinning. The speed with which the top fixture spins can be varied over the course of the test. The sample’s resistance is correlated to the shear stress affecting it; this shear stress [Pa] can be plotted against the speed of the upper fixture [1/s]. The slope of this plot is the viscosity of the sample in Pa*s. If this plot is linear, the fluid is called Newtonian, such as the graph for honey below. If the slope increases as the speed increases, the sample is shear thickening, such as for oobleck (a mixture of cornstarch and water). If the slope decreases as the speed increases, the sample is shear thinning, such as ketchup.

Additional Reading

https://wiki.anton-paar.com/us-en/basics-of-rheology/

https://www.whoi.edu/cms/files/lecture01_28325.pdf

https://pages.mtu.edu/~fmorriso/cm4650/lectures/Chapter10_Rheometry.pdf

https://www.sciencedirect.com/science/article/pii/000925098585051X

https://www.sciencedirect.com/science/article/pii/S0079670017300035

Written by Porter Biehler