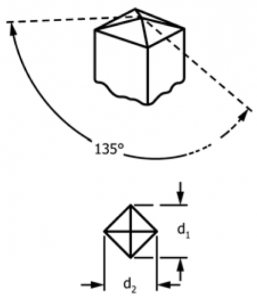

Hardness is defined as a material’s resistance to permanent deformation such as penetration or scratching. Static indentation tests are one way to determine hardness. For static indentation, a cone, pyramid, or ball is forced into the surface of the material. The relationship between the load applied for a given length of time and the area or depth of the indentation indicates the hardness. In Vickers hardness testing, a square pyramidal diamond indenter with specified face angles is used (see figure below).

After the pyramidal diamond tip (indenter) is pressed into the test sample at a perdetermined load (F[N]), the indentation on the sample is measured using a microscope. The lengths of the two diagonals (d1 and d2 in mm) are then measured (see figure above). The two measurements are converted into a Vickers hardness (HV) value using the following equation:

HV = 0.1891 * {F[N] /d1[mm] * d2[mm]}

Sample Preparation

For a high-accuracy measurement, the test should be performed on a flat specimen with a polished or prepared surface. The quality of the required surface is dependent on the force used. In all tests, the indentation perimeter and depth should be clearly defined when observed by the microscope.

Testing

In the Materials Characterization Lab at the University of Utah, the Instron can be used as the indenting machine. The surface area of the test specimen should be perpendicular to the indenter. In order to obtain the measurements of the diagonals of the indentation, a microscope such as the Tabletop SEM can be used.

A higher load on the sample forms a larger indentation with better measurement resolution, which can provide better results.